A total solutions partner

Having started in 1948 as a manufacturer of steel tubulars for pressure vessels and jacket foundations. We redefined our business in the year 2000 by focussing on the emerging offshore wind energy market. We are a step ahead in monopile foundations for offshore wind turbines. Sif’s business model was based on ‘build-to-print’ manufacturing of monopiles.

To achieve this position, Sif is optimising its fabrication assets to meet mainstream market demand, developing offshore wind foundation design engineering and integrated transition piece alternatives, whilst providing logistics and marshalling services and strengthening Sif’s competences for an EPC (Engineering-Procurement-Construction) role.

Manufacturing facilities located outside Europe are subject to constraints in terms of return- horizons and available support competence from the Netherlands. Sif operates in a stimulating and rewarding environment that attracts highly qualified personnel, suppliers, and other business partners. Sif is driving scale and optimization of offshore energy production capacity. The company thereby plays an important part in the energy transition to reduce carbon emissions and slow down global warming.

Shaping tomorrow. Performing today.

Sif is leading in offshore foundations and delivers quality on time, safely and within the agreed budget. We make good on this promise because of our critical approach to the preliminary stage.

Our dedicated specialists optimize each project on design, feasibility, coating and logistics. We want to ensure our production and the installation processes are efficient and cost optimal by working closely with our clients.

We also think beyond today's projects. By considering tomorrow and keeping a close eye on market developments, we adapt to the changing needs of market participants. We use our knowledge, experience, and inventiveness for product development and innovation. This is how we actively help shaping the future of offshore wind energy.

Our competences

- More than 2.000 monopiles produced

- Highly automated production processes

- Early and high involvement with our customers

- Powerful partnerships

- Unique know-how and expertise in rolling and welding

- Financial stability

- Proven track record of delivery of high quality in time within budget

- Thorough quality, health, safety and environmental procedures

Key data Sif production site

4-5

monopiles per week

10

tons/m2

300,000

tons

62

hectares

600 15.6

meters length

meter draught

Ro-ro quay

Milestones

- 2020 Sif’s 2000th monopile

- 2019 Commissioning Haliade-X on Sif terminal

- 2019 Extension of 20 hectares at Maasvlakte 2 for marshalling and logistic services

- 2017 Sif again number 1 in the Manufacturing top 100 of MT magazine

- 2017 First load-out at Maasvlakte 2

- 2016 Sif is number 1 in the Manufacturing top 100 of MT magazine

- 2016 Sif is listed at Euronext

- 2016 Expanding to 42 hectares at Maasvlakte 2 - Rotterdam

- 2015 First pile driving for Sif at Maasvlakte 2

- 2010 Building of hall 12

- 2008 Building of hall 10 and 11

- 2002 Building of hall 9

- 2000 Strategy change: from pressure vessels to offshore foundations

- 1993 Awarded the 'Van Landschot Export Prize' and first ISO certificate

- 1983 Building of hall 7 and 8

- 1978 Sif receives ASME certificate

- 1978 Building of hall 4, 5 and 6

- 1974 Building of hall 3

- 1972 First offshore client for Sif

- 1972 Building of hall 1 and 2

- 1971 Sif builts first production halls and office in Roermond

- 1961 New factory in Helden-Panningen

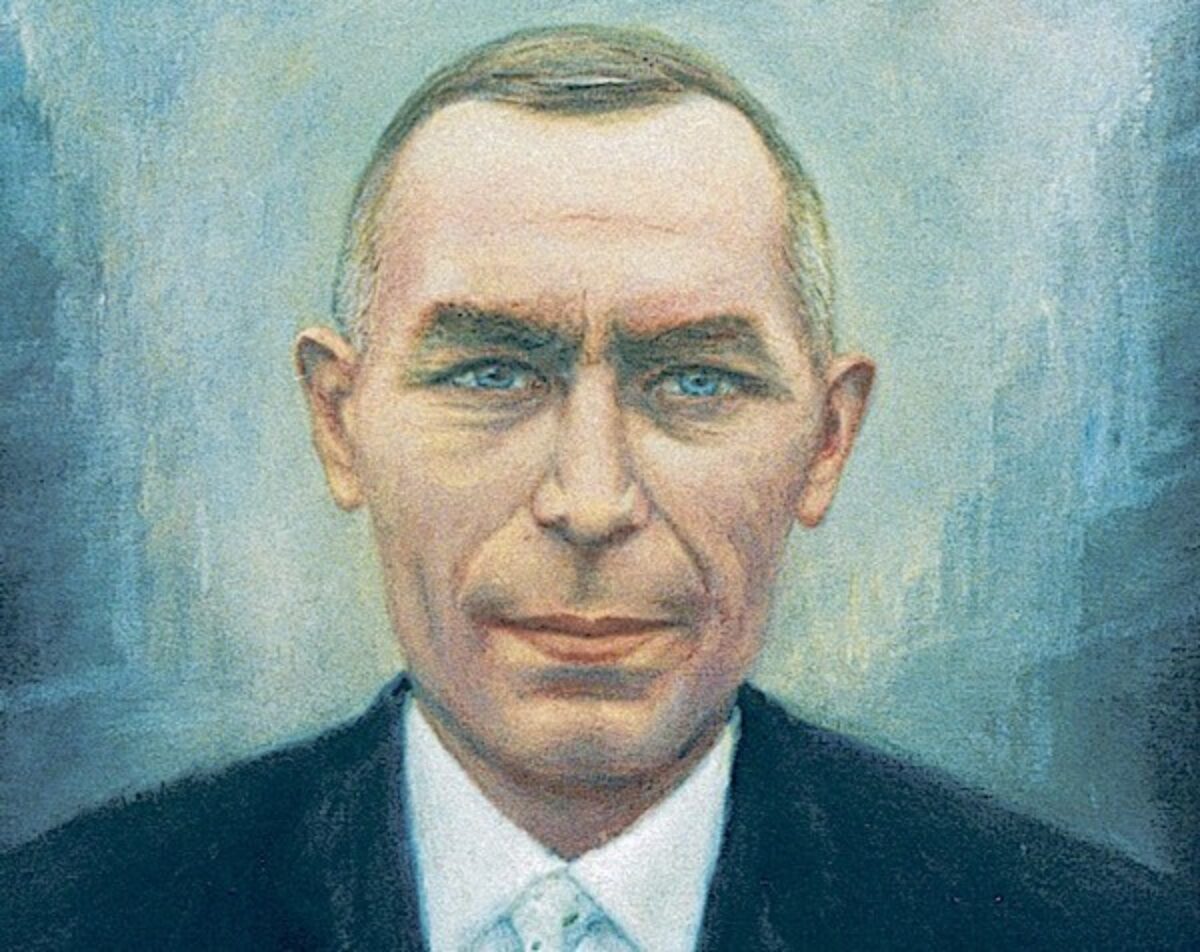

- 1957 Jan Jacob Schmeitz takes over all shares and becomes sole owner of Sif

- 1954 Silemetal outgrows locations and starts building a new location in Sittard

- 1952 Silemetal enters in a joint venture with Sif

- 1948 Jan Jacob Schmeitz founded Silemetal in Sittard